Boosting Productivity in Facilities Maintenance with Modern Aerial Lift Technology

Facilities maintenance teams face a steady flow of tasks that require safe access, quick problem-solving, and consistent results, both indoors and outdoors. From servicing lighting and HVAC systems to handling repairs in high or hard-to-reach areas, the work demands reliable tools that keep daily operations running smoothly. Modern aerial lift technology has become an essential part of that workflow, helping technicians complete tasks faster while reducing the physical strain and safety risks that come with ladders and scaffolding. Let's explore how aerial lifts support productivity across different facility types and why they have become a practical asset for maintenance teams looking to improve efficiency.

How Aerial Lifts Support Modern Facilities Maintenance

Aerial lifts give maintenance teams a dependable way to reach overhead systems, access elevated areas, and move efficiently through busy buildings. Instead of relying on time-consuming scaffolding setups or unstable ladders, technicians can position themselves quickly and work from a stable, secure platform. This shift allows facilities staff to complete more tasks in less time while maintaining steady control over every stage of the job. The result is fewer delays, smoother workflows, and a maintenance process that keeps buildings operating safely and consistently.

Improved Safety for High-Access Tasks

Safety is one of the most significant advantages aerial lifts bring to facilities maintenance. Working at height is a routine part of managing lighting, HVAC components, groundskeeping, and building systems, and ladders can limit stability in these situations. Aerial lifts provide a secure platform that helps technicians maintain proper balance, avoid overreaching, and stay positioned exactly where they need to be. This reduces the risk of falls and minimizes strain during repetitive or physically demanding work, creating a safer environment for both staff and building occupants.

Faster Completion of Routine Maintenance

Aerial lifts help maintenance teams move through daily tasks with far less setup time. Instead of assembling scaffolding or repositioning ladders repeatedly, technicians can transition from one area to the next with minimal interruption. This efficiency is especially useful in environments where multiple repairs or inspections are required in a short period. The ability to reach various points quickly without repositioning the lift allows teams to complete lighting changes, filter replacements, cleaning, and general upkeep in a more streamlined and productive workflow.

Better Reach in Tight or Confined Spaces

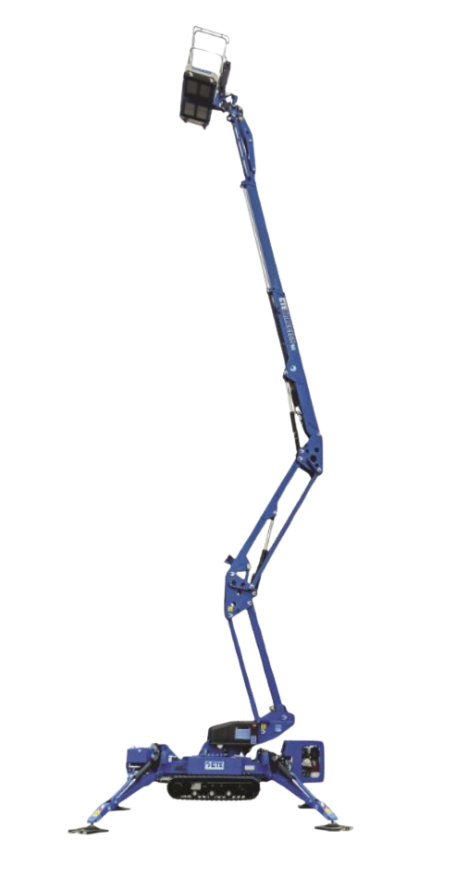

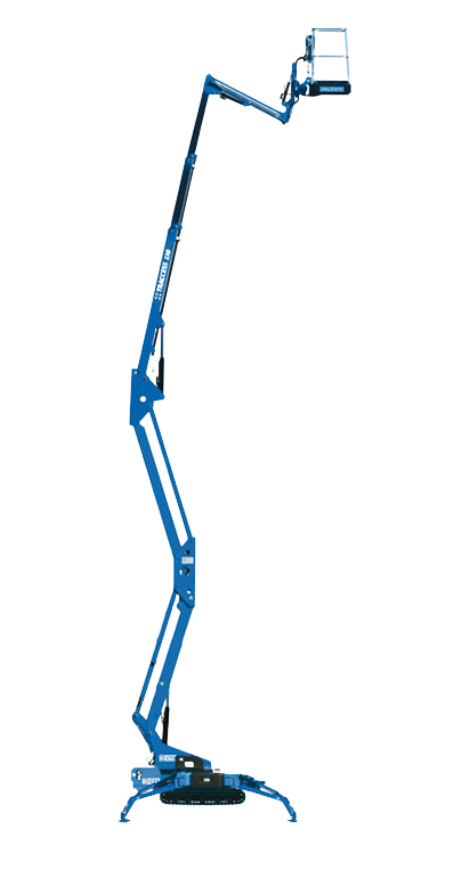

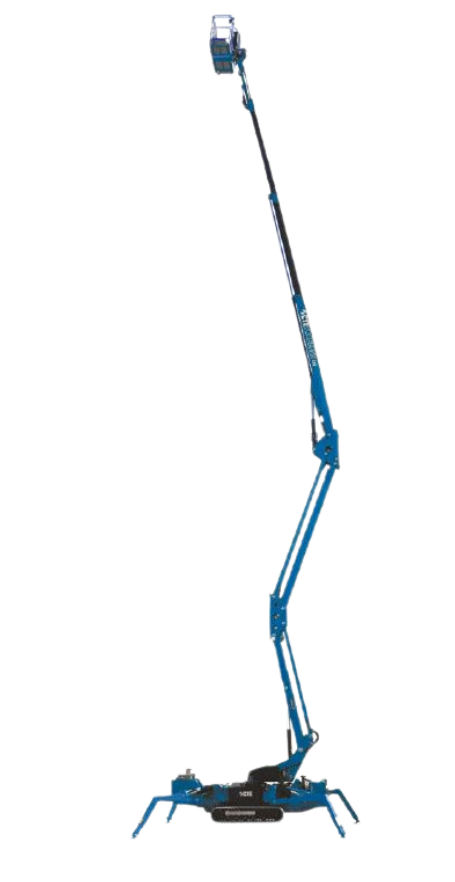

Many facilities include narrow hallways, atriums, indoor pools, and areas that are nearly impossible to access with traditional equipment. Compact aerial lifts, like the CTE TRACCESS line, are designed exactly for these challenges. Their smaller footprint and narrow tracks allow maintainers to move through doorways and aisles, while their hybrid/bi-energy power enables quiet and emission-free use. With extensive, unrestricted outreach, they can reach fixtures such as lights above pools or high atrium ceilings without disturbing operations. This makes them one of the most versatile lift solutions for facilities.

Precision Positioning for Delicate Work

Certain maintenance tasks require careful movement and precise placement, especially when working around sensitive equipment, wiring, or mechanical systems. Aerial lifts offer smooth, controlled maneuvering that helps technicians reach the exact spot they need without overextending or risking accidental contact with surrounding structures. This precision supports detailed work like installing fixtures, adjusting HVAC components, repairing signage, or handling electrical connections, ensuring tasks are completed accurately and without unnecessary disruption.

Types of Maintenance Tasks Supported by Aerial Lifts

Tracked aerial lifts, compact boom lifts, and other high-access equipment support a wide range of maintenance responsibilities across commercial, industrial, and institutional facilities. Their ability to reach elevated work areas safely and efficiently makes them valuable tools for completing essential tasks without disrupting building operations.

Lighting Repairs and Upgrades

Technicians can reach ceiling fixtures, LED panels, atrium lighting, and exterior building lights with steady positioning. This helps streamline bulb replacements, fixture repairs, and energy-efficient lighting upgrades.

HVAC Servicing and Inspections

Many heating and cooling components sit high above the floor or behind equipment. Aerial boom lifts make it easier to access vents, ductwork, sensors, and rooftop systems during routine inspections or repairs.

Fire Alarm and Sprinkler Maintenance

Compact tracked lifts allow teams to reach alarms, sprinkler heads, and safety devices located in high or awkward positions. This supports code compliance and prevents equipment failures.

Cleaning and Sanitization

High ceilings, beams, and overhead surfaces can be cleaned more effectively with a secure platform. This is especially valuable in warehouses, production areas, and large public buildings.

Painting, Finishing, and Surface Care

Boom lifts help crews reach walls, trim, and structural beams in open lobbies, gyms, and multipurpose spaces, improving accuracy and reducing setup time.

Signage, Display, and Banner Installation

Facilities with regularly changing displays or wayfinding systems benefit from quick access to mounting points without relying on ladders or permanent scaffolding.

General Building Upkeep

Everything from ceiling tile replacement to conduit checks becomes easier with high-access equipment that helps technicians work efficiently and stay properly positioned.

Conclusion

Modern lift technology has become a dependable resource for facilities maintenance teams working across commercial, industrial, and institutional settings. By offering safer access, smoother maneuvering, and reliable reach in both open and confined spaces, these machines help technicians complete daily tasks with greater consistency and less interruption. From lighting and HVAC work to cleaning, repairs, and general building upkeep, tracked and compact aerial lifts support a more efficient maintenance workflow that keeps facilities operating at their best.

Get a Quote from CTE North America

For teams interested in adding a compact, high-access solution to their maintenance equipment, CTE North America can help you explore available aerial lift models for sale and find the right fit for your facility. All CTE lifts come equipped with a battery or an electric motor in addition to their fuel-powered engines, making them the ideal solution for indoor and outdoor maintenance. Contact our team to request a quote, compare options, or learn more about TRACCESS solutions designed to support safe and productive building maintenance.

Search Our Products

Contact CTE North America

Questions? Get in touch with our main office by contact us online >

- or -

Call (860) 656-9077

Share